Chill-cast non-ferrous alloy foundry and machine shop established in 1976 in the Brescia area (100 km from Milan in the most industrialised area of Northern Italy).

Our family-owned business operates on a lean management structure, assuring a rapid decision-making process. With decades of experience, we can adapt and execute investment and production decisions to meet the most demanding customer requirements and new market opportunities.

With more than 100 employees, eight thousand square meters of production facilities, fifteen thousand square meters of land, and long-term supply chain partnerships, Kupral Spa is well-positioned to meet current and future growth demands. Our engineering, manufacturing, and management expertise supports the most demanding projects through concept, design validation, value analysis and production in order to offer lowest total cost solutions.

Reliability and quality are fundamental strengths throughout our specialty casting production in copper alloys (tin, aluminium, manganese bronzes and brass) and aluminium alloys. Any design can be supplied as-cast or fully machined to the most demanding requirements. Internal engineering and mold-making capabilities allow full control of tool making and quality, as well as best delivery timing from concept to production.

Value added services include special finishing, heat treatment, powder coating and other operations needed to provide ready-to-assemble components to your production line. Ongoing technology investment ensures optimum scheduling and production efficiency.

CNC production capabilities include horizontal machining centres with automatic pallet systems, CNC lathes with live tooling, and all necessary inspection and assembly equipment.

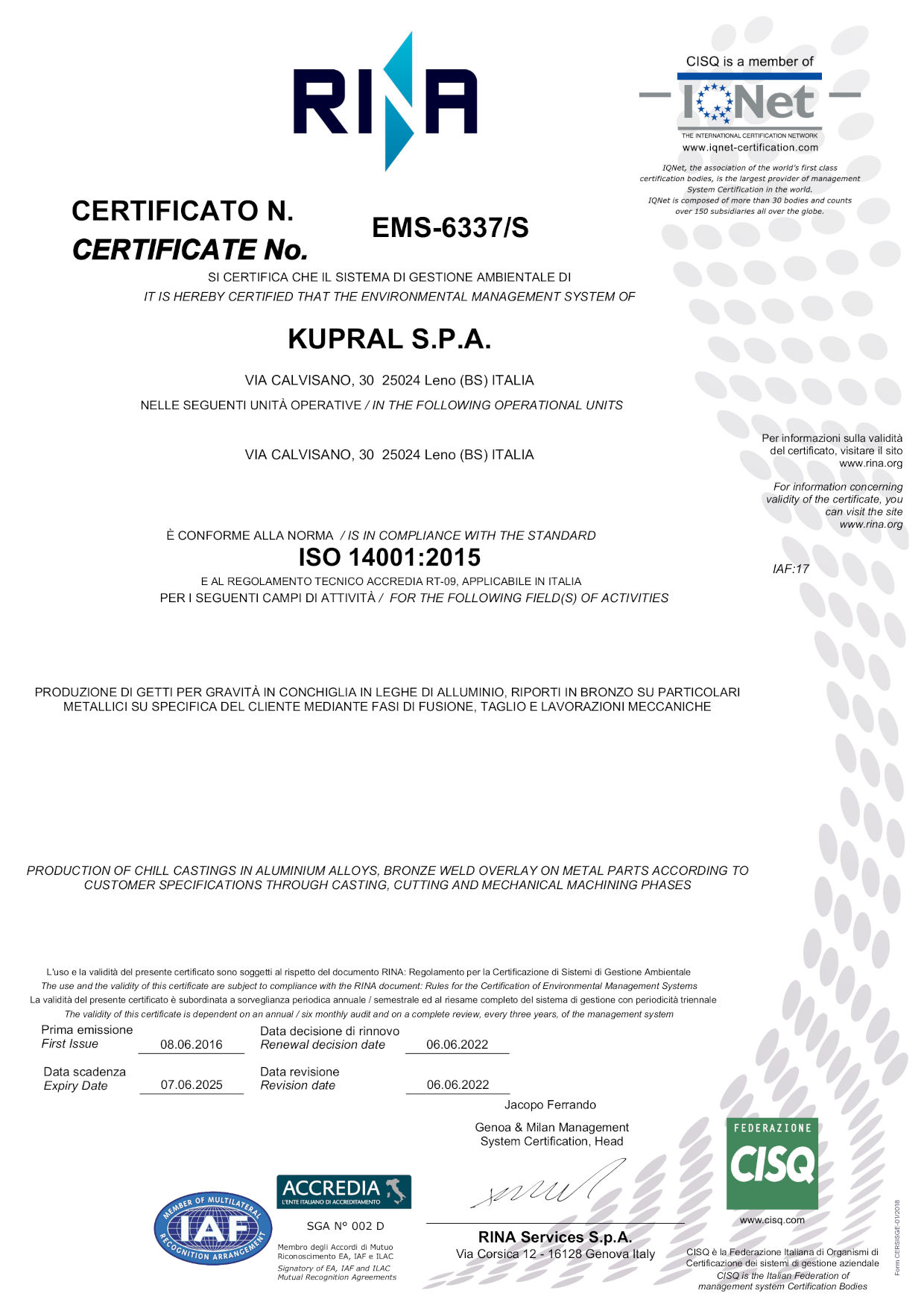

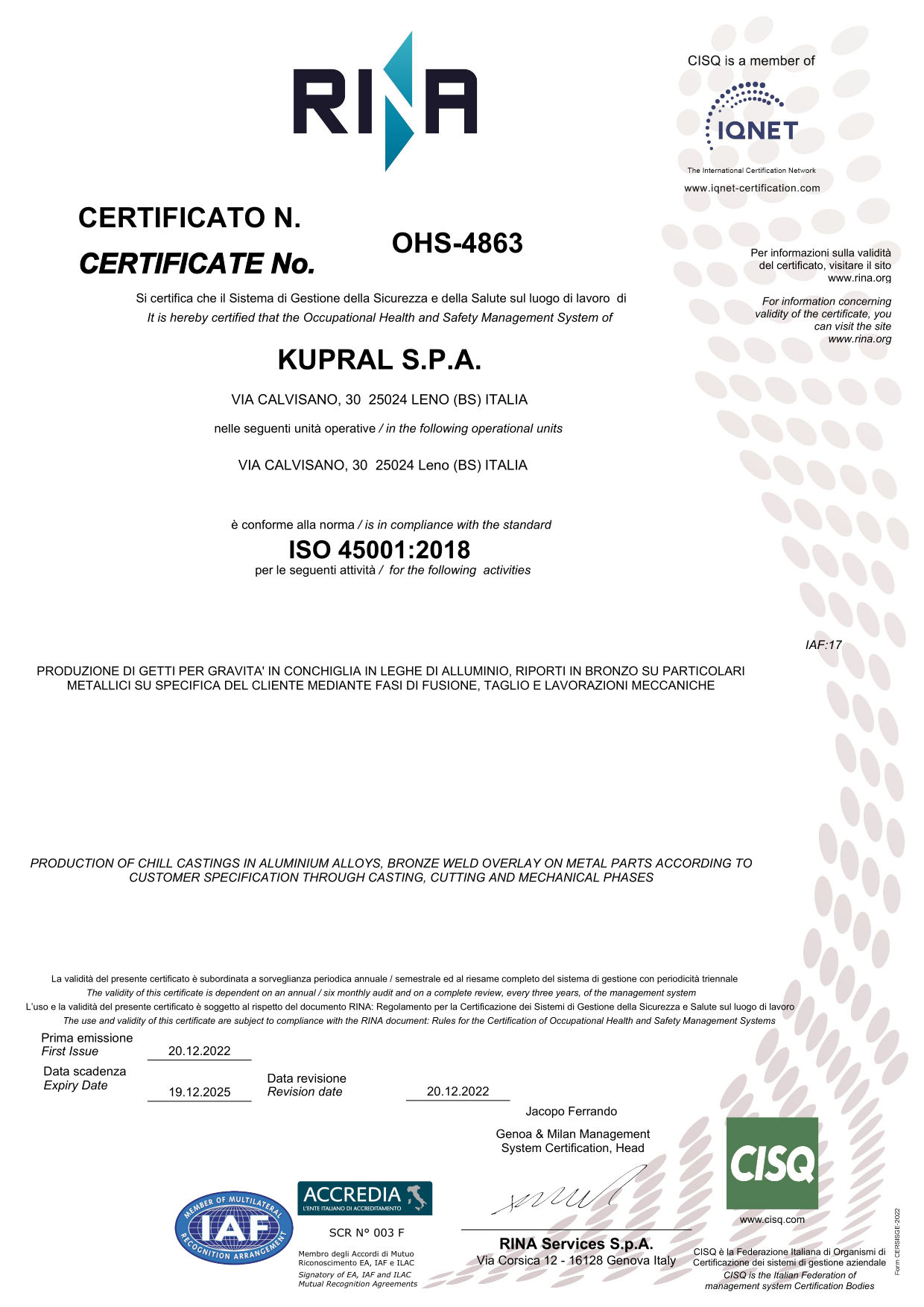

ACCREDITATION

KUPRAL SPA holds environmental certification (AIA).

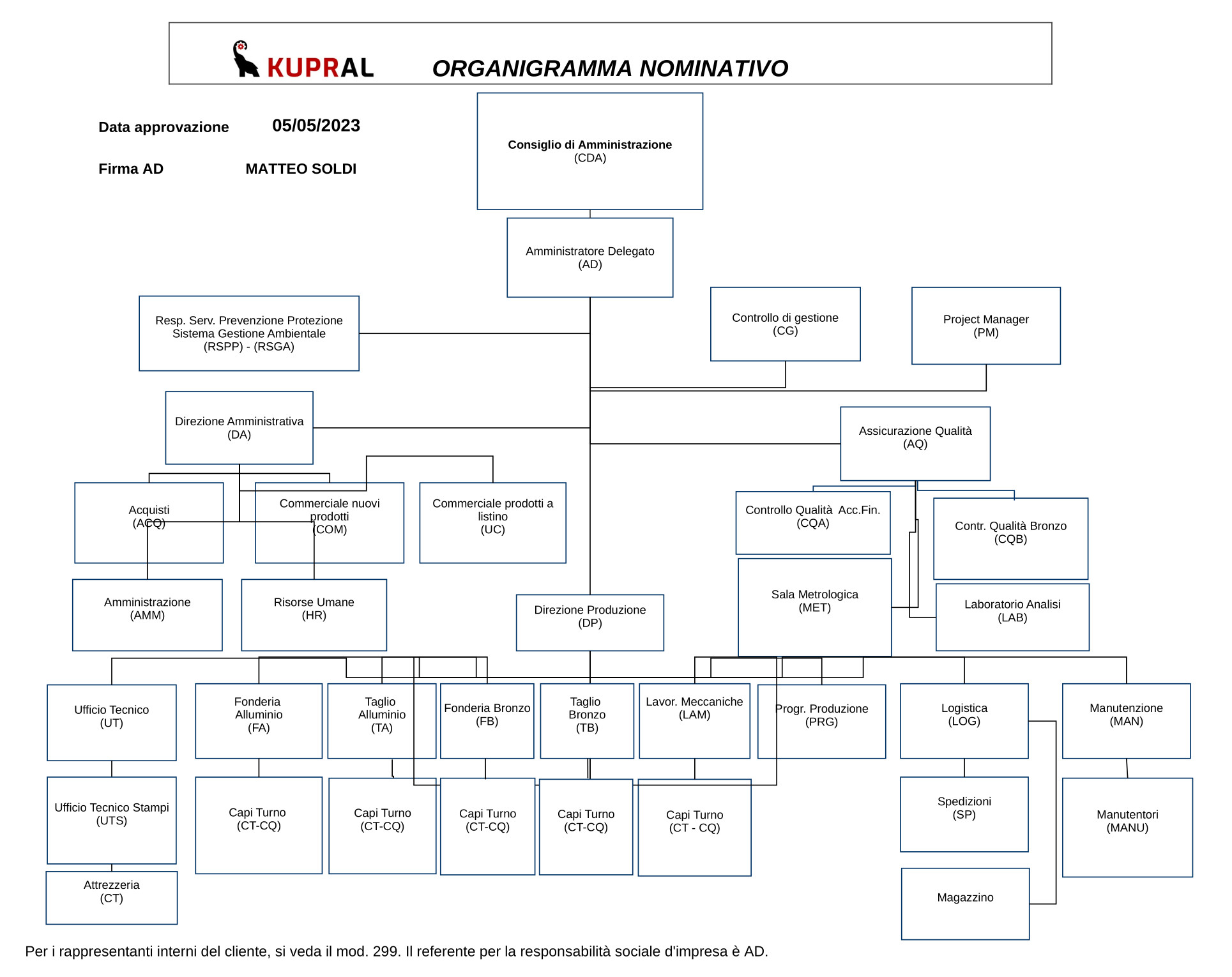

ORGANIZATION